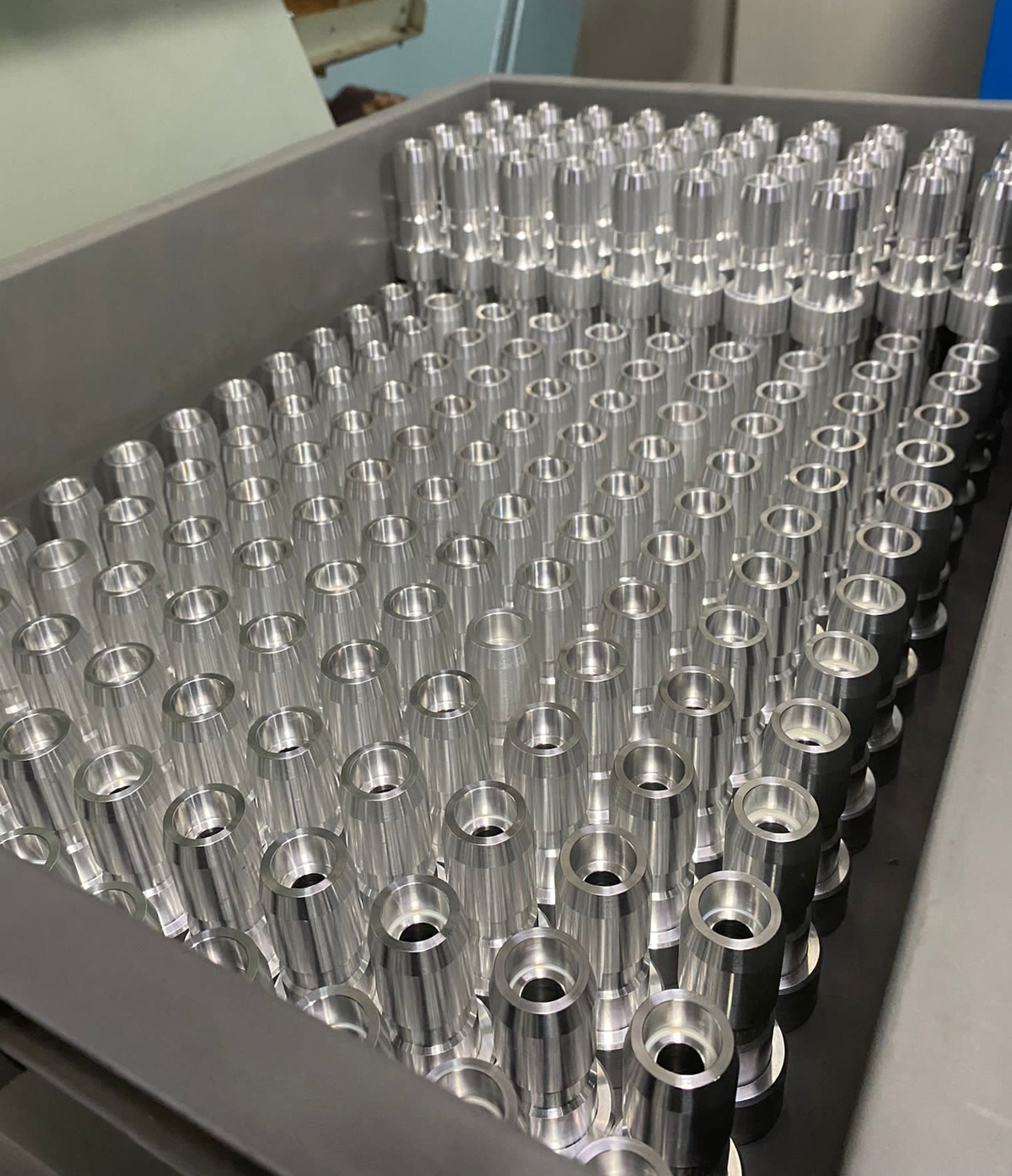

Machining

At Ortus Automotive, we add value to our customers’ production processes by delivering high-precision and high-quality machining solutions that meet international standards. Thanks to our modern CNC machining centers and experienced team of experts, we successfully complete projects of varying scales, from small batches to high-volume production.

Our machining processes cover every stage, including needs analysis, material selection, detailed machining planning, high-precision production, in-process inspections, surface treatments, assembly, and final quality control. Through this comprehensive approach, we guarantee error-free dimensions, excellent surface finish, and superior mechanical performance in your parts. Our machining capabilities are the preferred choice for producing critical components in industries such as defense, automotive, aerospace, energy, and industrial machinery.

Ortus Automotive’s expertise in machining includes:

- Needs Analysis and Technical Consulting: We thoroughly examine your project’s specifications and application area to determine the most suitable production method and materials. Cost-effective and high-quality solutions are developed to optimize your processes.

- Material Selection: The ideal metal or alloy is selected based on mechanical properties, machinability, durability, and operating conditions. Material quality is critical for achieving optimal performance and longevity of the manufactured parts.

- Machining Planning: Using CAD/CAM systems, we optimize machining sequences, tool paths, cutting speeds, and other parameters. This reduces production time while improving dimensional accuracy.

- Precision CNC Machining: On our 3- and 5-axis CNC machines, we machine complex parts with tight tolerances at high speed and precision. Complex geometries are produced in a single setup, ensuring repeatable and consistent quality.

- In-Process Inspections and Measurements: By performing checks at specific stages of production with advanced measuring devices, we identify and correct any errors early, ensuring flawless parts.

- Surface Treatments: Surface grinding, polishing, or coating processes are applied to improve wear resistance, corrosion protection, and aesthetics. The surface finish is brought to levels that fully meet customer standards.

- Assembly and Functional Testing: Manufactured parts are assembled when required, and their mechanical fit is checked. Operational performance tests are conducted to ensure reliable delivery without defects.

- Quality Control and Certification: Every part is thoroughly inspected for dimensional accuracy using our coordinate measuring machines (CMM) and other advanced equipment. Measurement reports and quality certificates are prepared as needed and provided to our customers.

At Ortus Automotive, with our modern machine park, commitment to international quality standards, and customer-oriented service approach, we offer reliable and high-quality machining solutions that strengthen your competitiveness in the industry.